Navigation

- Akumulační nádrže

- Autoklávy

- Betonárky

- Čerpací stanice

- Obalovny živičných směsí

- Ocelové konstrukce

- Ocelové nádrže

- Sila, násypky a zásobníky

- Telekomunikační věže a rozhledny

- Tlakové nádoby

- Velkorozměrové obrábění CNC

- Velkorozměrové ocelové potrubí

- Vodní elektrárny

- Výrobky z nerezu

- Výrobní zařízení

- Montáž, servis a doprava

- Politika ISM

- Projekce

The continuously increasing requirements for environmental protection force truck manufacturers to reduce the amounts of pollutants in exhaust gases accordingly in order to comply with the EURO 4 emission standards (Directive 2003/76/EC) in force from October 2005. In order to meet NOx limits the truck manufacturers use an additive called AdBlue. This liquid is added, by a dosing pump, into the flow of exhaust gas and by a catalytic reaction it decomposes into ammonia. Ammonia then reacts with nitrogen oxides generated by the combustion process to form nitrogen gas and water vapour. By that process the level of NOx in exhaust gas is considerably reduced.

AdBlue is clear colourless liquid consisting in 32.5% aqueous solution of synthetic urea of high purity.

AdBlue is hazardous neither to human health, nor to the environment, but it must be unconditionally stored in well closed containers. AdBlue will freeze at the temperature of -11 °C and, preferably, it should be stored at a place, where temperatures will not fall below 0 °C.

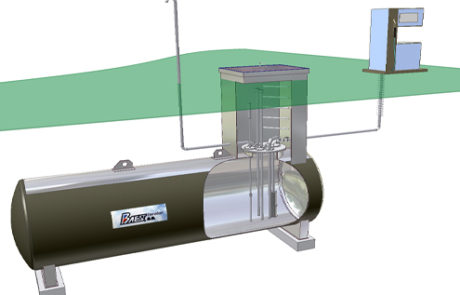

BEST BLUE is a complete technological unit intended for AdBlue delivery and underground storage.

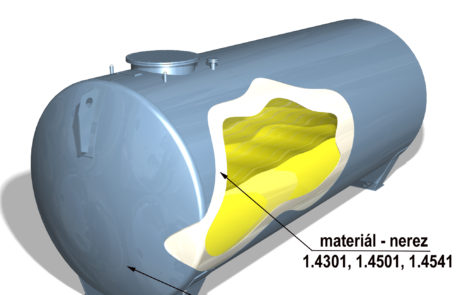

The equipment consists of a buried double-shell tank, whose inner shell is made of stainless steel of the 1.4301 grade. Its outer shell is mad of the S 235JRG2 steel and is provided with soil humidity insulation. The tank must be placed at the non-freezing depth of 1500mm at least.

The product range comprises the sizes of: 1; 2.5; 5; 10; 12; 16; 20; 25m3

The tank is fitted with:

- intake and filling stainless fittings

- level measurement including overfill watching

- electronic monitoring of delivery

- stainless steel pump.

AdBlue is transported from the buried storage tank to the dispenser by means of the stainless pump and stainless piping.