Navigation

- Akumulační nádrže

- Autoklávy

- Betonárky

- Čerpací stanice

- Obalovny živičných směsí

- Ocelové konstrukce

- Ocelové nádrže

- Sila, násypky a zásobníky

- Telekomunikační věže a rozhledny

- Tlakové nádoby

- Velkorozměrové obrábění CNC

- Velkorozměrové ocelové potrubí

- Vodní elektrárny

- Výrobky z nerezu

- Výrobní zařízení

- Montáž, servis a doprava

- Politika ISM

- Projekce

The silos are available in the capacity range of 30, 40, 50, 60, 70, 80, 90, 100 and 120m3, being divided into either horizontal or vertical sections. In general, the cement silo is usually equipped with aeration equipment protecting it from material arching and with filters arresting fine particles entrained by air escaping from the silo during filling. The silo is fitted also with various technological and inspection holes, a filling system, an exterior ladder and a walkway gallery. The silo shall be provided also with a system for monitoring the material quantity kept in store.

The system of storage silo is provided with necessary equipment for the receipt and delivery of loose materials such as pneumatic placers as well as bucket, belt and worm conveyors. The silos are made of steel of the S235JRG2 grade and may be provided with abrasion resistant (HARDOX) interior lining on customer‘s request. Silos designed for the food industry are made of stainless steel, or their internal surfaces can be provided with coatings certified for use in food applications. Exterior surfaces are coated with durable epoxide or polyurethane coating systems of high quality and weathering resistance.

Silo Technical Design:

Silo types:

-

single-chamber silos

-

multiple chamber silos – vertically divided

-

multiple chamber silos – horizontally divided

-

filler towers.

Silo layout:

-

in a line

-

in a square

Standard size ranges (storage capacities):

-

Single chamber types: – 20, 30, 40, 50, 60, 80, 100, 120, 150m3

-

Two-chamber types: – 10/10 20/20, 30/30, 40/40, 50/50, 60/60, 75/75m3

-

Multi-chamber silos: to customer‘s requirements.

Execution:

-

mounted on a supporting structure

-

without any supporting system – with suspension brackets welded on, or

-

without any supporting system- with a mounting collar on the shell

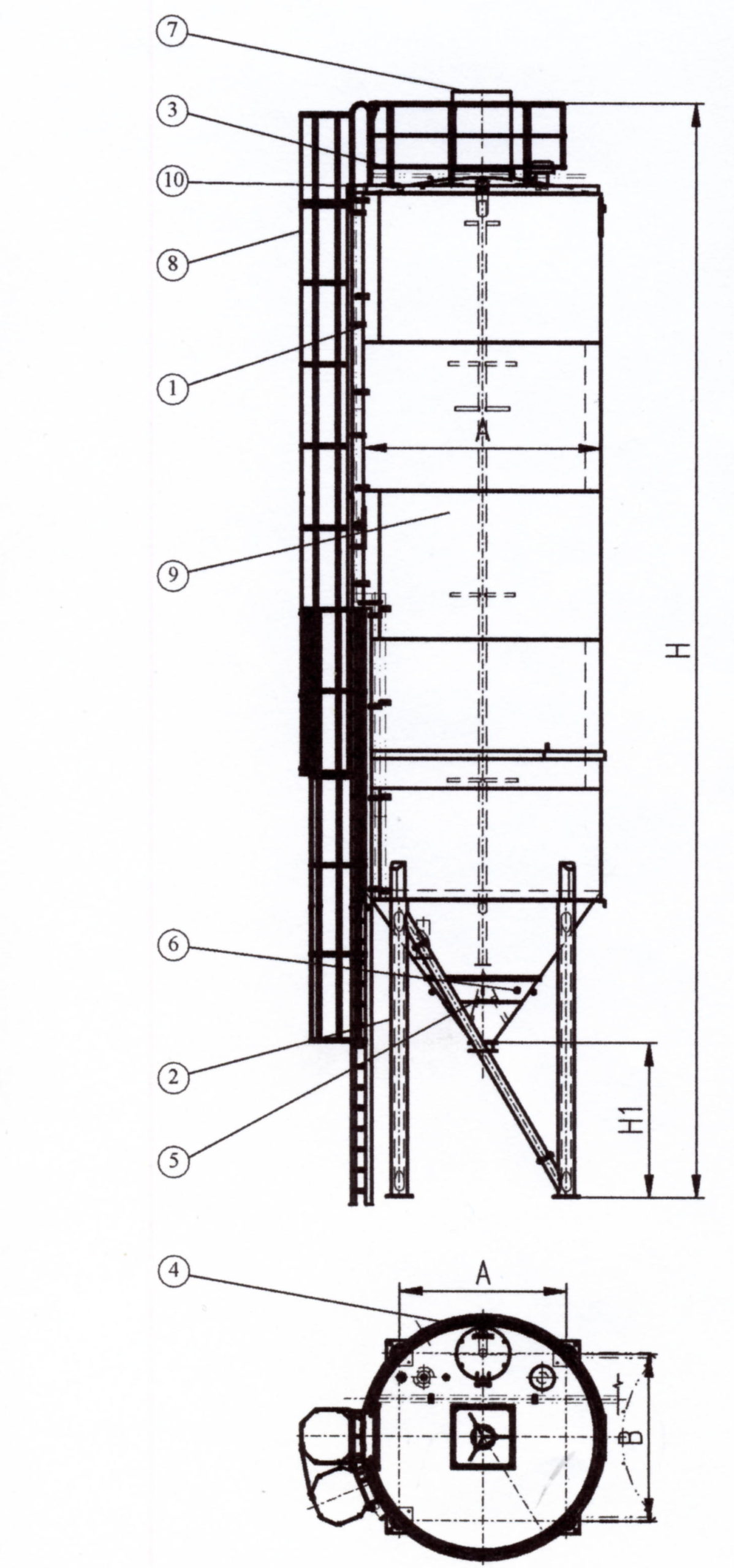

LEGEND:

- STORAGE BIN

- LOAD BEARING STRUCTURE

- PLATFORM WITH RAILING

- MANHOLE

- SHUT-OFF VALVE

- AERATION SYSTEM

- FILTER

- PRESSURE RELIEF VALVE

- LADDER WITH SAFETY CAGE

- STOCK LEVEL PROBE

| type (capacity) m3 |

diameter D mm | width H mm | heigtht H1 mm | footing AxB mm | weight kg |

| BN-30 | 2900 | 9496 | 1950 | 2050×2050 | 3534 |

| BN-40 | 2900 | 11000 | 1950 | 2050×2050 | 3966 |

| BN-50 | 2900 | 12500 | 1800 | 2050×2050 | 4398 |

| BN-60 | 2900 | 14000 | 1800 | 2050×2050 | 4720 |

| BN-80 | 3200 | 12731 | 2075 | 2250×2250 | 5905 |

| BN-100 | 3200 | 14884 | 2075 | 2250×2250 | 5643 |

| BN-120 | 3200 | 15515 | 2144 | 2250×2250 | 6200 |

| BN – typy: Svisle dělená sila: BN 30+30 BN 2×80 BN 2×100 Sila umístěná nad sebou – věžové provedení |

|||||