Navigation

- Akumulační nádrže

- Autoklávy

- Betonárky

- Čerpací stanice

- Obalovny živičných směsí

- Ocelové konstrukce

- Ocelové nádrže

- Sila, násypky a zásobníky

- Telekomunikační věže a rozhledny

- Tlakové nádoby

- Velkorozměrové obrábění CNC

- Velkorozměrové ocelové potrubí

- Vodní elektrárny

- Výrobky z nerezu

- Výrobní zařízení

- Montáž, servis a doprava

- Politika ISM

- Projekce

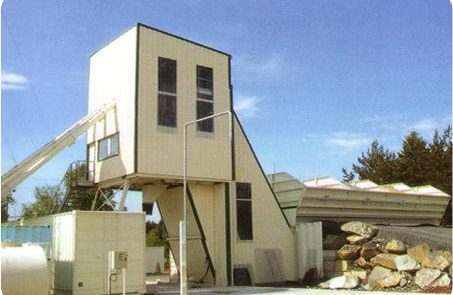

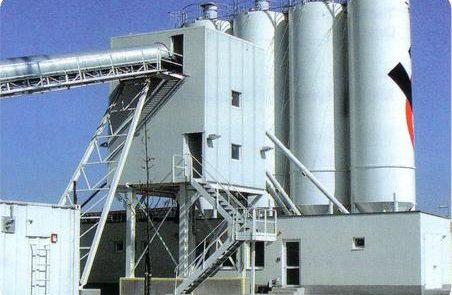

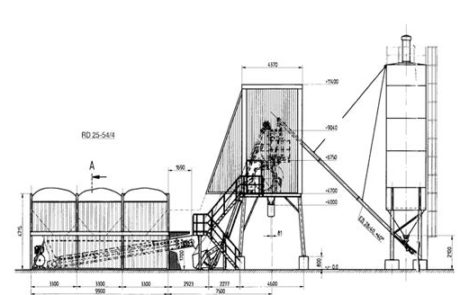

BAEST, Machines & Structures, a.s., introduces itself as the manufacturer and supplier of particular concrete mixing plant components and complete units.

BAEST, Machines & Structures, a.s., provides:

-

design, engineering and consulting services

-

project and production documentation

-

supplies of the technological equipment of its own manufacture

-

delivery, assembly/erection of the equipment and putting it into operation.

BAEST, Machines & Structures, a.s., supplies:

-

Tower Storage Silos

The cylindrical silos designed for storing cement and flue ash comprise the basis of cement handling systems. Material transport is provided by means of worm conveyors. In general, the cement silo is usually equipped with aeration equipment protecting it from material arching and with filters arresting material fine particles entrained by air escaping from the silo during filling. The silo is fitted also with various technological and inspection holes, a filling system, an outer ladder and a walkway gallery. The silo shall be provided also with system for continuous monitoring of the stored material quantity.

-

Cold Batching System

Cold batching systems are used for storing and delivering particular sand and aggregate fractions. The cold batching system consists of single hoppers, feeder belts, a collecting conveyor and a discharging belt conveyor. The hoppers are produced in standard capacities from 6m3 to 15m3 and provided with supporting steel structures. Other storage capacity hoppers may be manufactured upon customer‘s request.

-

Recycling Equipment

The recycling equipment serves for washing concrete residues out from a concrete mixing plant or a mixer truck. Washed aggregates are reused in the production process, while the wash water is reused as gauge water in concrete mixing operations.